Winterization, 11/25/2007

I was distracted by responsibilities at home last weekend, so I hadn't yet finished winterizing. I returned on Sunday with my father and Anthony (visiting for the holiday) for a quick cruise and to complete the remaining tasks. They were a big help, providing extra hands along the way.

I borrowed an oil change pump (a Jabsco flat tank, just like mine) from a friend at work. After a quick cruise, we set it to work while finishing off a few other tasks. I cleaned the sea water strainer, drained the raw water from the heat exchanger, and pulled the engine zincs. For the most part, the zincs were in good shape (better than 50% remaining), but they're inexpensive and a PITA to reach, so I changed them anyway before putting them back.

Good news: the oil change went fairly easily. Once I was reasonably sure that all of the oil was out of the engine, I moved the pump to the transmission oil and let it work there while I changed the main oil filter. Last time I changed the filter, I made quite a mess. This time, I took a layered approach: I set down an oil absorbent cloth, spread an opened trash bag over that, set a foil tray in the bag, and wrapped a 1-gallon ziploc around the filter while unscrewing it. The ziploc caught most of the oil, and the bit that I missed spilled fairly neatly into the foil pan. When it finished dripping, I installed the new filter and simply picked up the trash bag, letting the filter and foil pan fall right inside. Barely any spilled, so a few shop towels cleaned it right up.

After refilling the oil in the engine and transmission, I sucked 6 gallons of pink RV antifreeze through the raw water side, and then we called it a day.

Monday, November 26, 2007

Sunday, November 11, 2007

One And... Not Done

Winterization, 11/11/2007

Winterization, 11/11/2007We set out today to winterize the boat, hoping to finish in one day. Things didn't quite work out that way.

The fuel dock was first up. We filled the tank with diesel, and added biocide plus 32 oz. of Stabil. One interesting point here: our deck fitting for the fuel tank is narrow, and we usually look for fuel docks with a narrow nozzle to fit. Our normal fuel dock had only the wider high-capacity nozzle working this time, so we gave it a try. I just held it tightly against the opening, and it worked fine. Good to know. We then pumped out the holding tank, and returned to the dock.

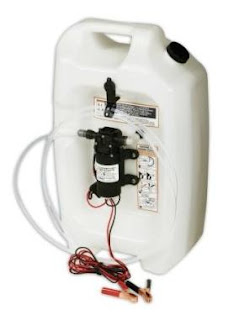

While Michele put the final coat of Cetol on the toe rail and hand rails, I started winterizing the systems. We have a Jabsco Flat Tank 12-volt oil pump (see picture) for changing the engine oil. It has a nice 3.5 gallon tank, perfect for our 11 quart engine capacity, plus 2 quart transmission oil capacity. I set the oil pump running so that it could extract the warmed-up motor oil while I worked on other tasks. While it was pumping, I drained the water tank, bypassed the water heater, and ran pink RV antifreeze through the water system, the head, and the A/C.

When I returned to the oil pump, I was dismayed to find it nearly empty. It has worked ok (albeit slowly) in the past, but this time it failed. The oil just came through at a drip, and after more than an hour, it had extracted only about 1 quart of oil. Unfortunately, I'll need to return next weekend with another pump to finish the job. The good news: the unit is just a year old, and has a 3-year warranty. Kudos to Jabsco: I called them, and they're sending a new pump, no questions asked. Outstanding! I hope they follow through; I'll be sure to post an update.

Next weekend: Finish the oil change, drain the raw water from the engine, change the engine zincs, and run pink antifreeze through.

Finished Brightwork

Teak Maintenance, 11/11/2007

Teak Maintenance, 11/11/2007Michele finished the toe rail and hand rails today while I worked on winterization chores. They look great. There's a bit of bleed onto the gel coat, but not so noticeable in person. I might try cleaning it up with acetone.

The starboard hand rail looks just a bit lighter than the port hand rail due to the sanding. Again, not very noticeable in person.

The starboard hand rail looks just a bit lighter than the port hand rail due to the sanding. Again, not very noticeable in person.

Tuesday, November 6, 2007

Brightwork: Second Coat

Teak Maintenance, 11/4/2007

We returned on Sunday to apply the second coat of Cetol to the toe rail, hand rails, and cockpit steps. The second coat took the two of us just 90 minutes. There definitely appears to be some variation in color between the areas that were bare and those that still had original coatings. It doesn't look bad, but I certainly can notice it. Eh, probably I'm the only one who will care. Maybe a third coat next weekend will reduce the contrast. I'll take pictures of the finished areas next week.

The upper hand rails were in good shape, so they are done. After two coats, they really look nice! Applying a maintenance coat to sections that were already in good shape was easy. So easy, in fact, that we wish we hadn't put it off, despite the extensive list of more important work. The penalty for delay is just too high. We won't make that mistake again.

Still to do: flybridge steps, flybridge bench seat, wheelhouse door, and swim platform. That seems like a lot, but it really shouldn't be too bad. Everything except the swim platform is in good shape and should just require a maintenance coat or two. The platform will need a full sanding, so we may take it off and bring it home for the winter.

We returned on Sunday to apply the second coat of Cetol to the toe rail, hand rails, and cockpit steps. The second coat took the two of us just 90 minutes. There definitely appears to be some variation in color between the areas that were bare and those that still had original coatings. It doesn't look bad, but I certainly can notice it. Eh, probably I'm the only one who will care. Maybe a third coat next weekend will reduce the contrast. I'll take pictures of the finished areas next week.

The upper hand rails were in good shape, so they are done. After two coats, they really look nice! Applying a maintenance coat to sections that were already in good shape was easy. So easy, in fact, that we wish we hadn't put it off, despite the extensive list of more important work. The penalty for delay is just too high. We won't make that mistake again.

Still to do: flybridge steps, flybridge bench seat, wheelhouse door, and swim platform. That seems like a lot, but it really shouldn't be too bad. Everything except the swim platform is in good shape and should just require a maintenance coat or two. The platform will need a full sanding, so we may take it off and bring it home for the winter.

Monday, November 5, 2007

Brightwork

Teak Maintenance, 11/3/2007

Teak Maintenance, 11/3/2007"Bright it should be, and work it is." -- unknown

I'm not sure of the origin of that expression, but it aptly describes the dreaded task of maintaining teak on a boat. Often, other boaters look at the brightwork on a boat with mixture of admiration and pity. Teak is beautiful, but it also brings visions of endless sanding and varnishing. The finished product, of course, is quite rewarding. Or so I've heard.

Nowadays, pigmented coatings like Sikkens Cetol are a common compromise. The application and maintenance process is much easier, and the pigment protects the wood from UV.

But, it lends a somewhat less appealing color than the mile-deep shine of traditional varnish. In our case, the decision to do it the easy way was made for us: The prior owner had already started with Cetol in 2004. Unfortunately, even with Cetol, we have our work cut out for us because we put off the project for too long, allowing the the finish to deteriorate quite badly in some areas. In those areas, bare teak has been exposed all year, and it has weathered gray. We really should have addressed the situation sooner, but we were otherwise occupied.

But, it lends a somewhat less appealing color than the mile-deep shine of traditional varnish. In our case, the decision to do it the easy way was made for us: The prior owner had already started with Cetol in 2004. Unfortunately, even with Cetol, we have our work cut out for us because we put off the project for too long, allowing the the finish to deteriorate quite badly in some areas. In those areas, bare teak has been exposed all year, and it has weathered gray. We really should have addressed the situation sooner, but we were otherwise occupied.We started Saturday morning with the worst of it: the toe rail, hand rails, and cockpit steps. The hand rails were in mostly decent shape except for the forward-starboard rail, which was chipping and peeling pretty badly. The toe rail was moderately deteriorated all the way around. The deterioration increases the prep work substantially, since it requires sanding in addition to general cleaning. We followed these steps on all the deteriorated wood:

- Scrub thoroughly with a scouring pad, mild boat soap, and water

- Towel-dry

- Sand with 150-180 grit sanding pads to remove any flaking, and to take weathered areas down to clean wood

- Vacuum the dust

- Wipe with acetone to clean any remaining dust or oils

- Allow to air dry

- Brush on first coat of Cetol Light with a natural bristle brush

We freehanded the Cetol application, rather than taping off all of the surrounding area. That seemed to be the unanimous recommendation from others, given the time and difficulty involved with taping. A shop towel dampened with acetone works great for cleaning up any mistakes.

We freehanded the Cetol application, rather than taping off all of the surrounding area. That seemed to be the unanimous recommendation from others, given the time and difficulty involved with taping. A shop towel dampened with acetone works great for cleaning up any mistakes.The process took the two of us about four hours. Teak is pretty soft, so sanding was easier than I expected. We only sanded to the point where all the flaking areas of Cetol were removed, which left the wood partly coated, and partly bare (click the pictures for closeups). My hope is that this will be adequate, but I'm concerned that the bare areas will show lighter than the other areas when we're finished. I expect that we'll need three coats minimum on the bare areas.

Subscribe to:

Posts (Atom)